Have you heard about PET foam boards? Yes, that’s right; the foam boards are manufactured from the same material used in plastic water bottles, which is sustainable alternative to non-recyclable thermoplastics and other materials. But what exactly is recycled PET foam core board? The recycled PET foam core boards are manufactured from recycled PET bottles and PET products. Recycled PET foam core board is a lightweight, rigid closed cell foam based on its primary polymeric unit polyethylene-terephthalate (PET). These are the same polymers found in most of our plastic water bottles today. PET foam boards are manufactured usually in closed-cell type, which attributes high density and weight to strength ratios, thus owing to their remarkable mechanical properties. As known for their excellent strength, durability, and easy workability, they became popular material to meet indoor and outdoor applications.

Recycled PET resins are heated and mixed with additives such as foaming agents, stabilizers, fillers, etc., to create a proprietary recycled PET foam base. This material is then cooled and extruded using heat, foaming agent, friction, and shear to form foam board. After entering the mold, the material is adjusted, and sheet edges are cut and sawn to form PET foam boards. The additives used in the manufacturing process significantly affect the end product's quality and performance. At APM, we commit to sustainability and the highest product quality and its performance. All the required raw materials and additives are locally sourced, and state-of-the-art manufacturing processes and production facility ensures the highest standard and sustainability. The PET resins we use to manufacture the PET foam boards and sheets come from recycled plastic bottles- this is our commitment and contribution to the circular economy. APM used recycled PET foam boards are halogen and CFC free.

PET foam core materials are used in APM panels and components are manufactured from 100% recycled PET materials. At APM, we use a combination of ocean recycled and municipality recycled PET materials. Our used recycled PET foam core boards are fire retardants, mold resistant, do not absorb water and moisture, and offer exception thermal and heat stability. It does not deform or go out of shape under extreme cold and heat. The material does not corrode under salt water or acidic rain, and importantly 70-80% lighter than MDF, wood chip board and other conventional materials. This helps to reduce weight whenever necessary, particularly projects where weight reduction is crucial without losing structural integrity and strength.

What kind of processing techniques are used at APM to turn recycled PET foam boards into useful items? We use several processing techniques to produce recycled PET foam core-based panels and components.

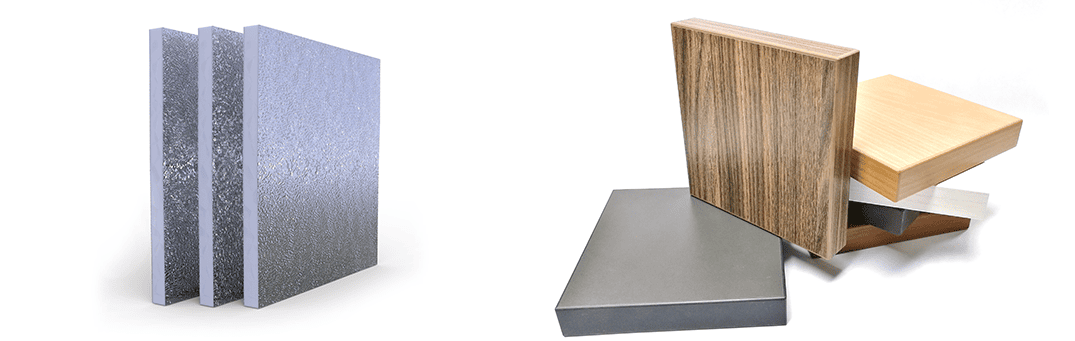

At APM, we laminate recycled PET foam core boards using a wide range of outer later materials (called skins) to improve stability, appearance and strength. Our lamination process completely depends on the end project and application. Depending on the end project and application we select the laminating materials and adhesives. At APM, we have a large selection of laminating materials such as thermoplastic laminate, high pressure laminate, phenolic laminate, fiberglass laminate, carbon fiber laminate, aluminum laminate and many others. At our production site we have state-of-the-art laminating and composite production equipment. We have the capacity to produce complex shaped and structured panels and components. At APM, we do complete custom production and fabrication depending on the project and application specifications.

Because of its excellent thermoplastic properties, recycled PET foam boards and laminated panels can be easily thermoformed by heating and pressure to give desired shape and dimensions. At APM, we have state-of-the-art machinery to produce complex shaped lightweight structural panels and components.

This processing is another way to make a structural composite panel to improve the core material’s mechanical and thermal properties. Pre-preg is a common term for composite materials that are “pre-impregnated” with desired resins and then hardened. This pre-impregnation is by various means depending on end-use and application. Contact us for your project specification.

There are hundreds of commercial applications of 100% recycled PET foam core-based panels and components. In the automotive manufacturing industry, PET foam core-based thermoform boards and laminated structures are commonly found in roofing, doors, ceiling, partition, and seat bottoms of the vehicles.

In the cruise and boat interior construction industry, PET foam core-based panels and components are used to manufacture door panels, interior decoration and furniture such as wardrobe, TV stand etc.

Acoustic insulation, sound absorption, and acoustic architectural panel. PET foam-based materials are most commonly used to improve acoustic insulation and sound absorption. At APM, we produce and fabricate a wide range of acoustic products and solutions for various applications. Contact us for your acoustic project.

Weight saving: PET foam core-based panels and components help to save 60-80% weight compared to MDF, wood chip board and similar core-based panels and components. This is greatly important for cruise and boating interior projects. Replacing conventional panels with PET foam core-based panels will improve fuel efficiency significantly, and as a result less greenhouse gas emission.

Mechanical and Physical Strength: PET foam core-based panels and components are known for its exceptional strength to weight ratio. Therefore, panels and components produced using PET foam core provide similar or better mechanical performance and physical strength compared to MDF, wood chip board and similar materials. The panels also provide similar screw retention performance.

Corrosion and weather resistance: PET foam core-based panels and components do not corrode in salt water or acid rain. The panels also provide exceptional cold and hot weather resistance performance. They do not deform and delaminate under extreme weather conditions. The panels do not absorb moisture and water, therefore susceptible to mold, microbes growth and bacteria.

Fire performance: Fire performance of PET foam core-based panels and components depend on the complete structure, i.e., PET core + Laminates + Adhesive. Usually, the panels and components provide B rated fire performance. In the event of fire, it does not produce toxic gases and severe smoke.

Service life and recyclability: Panels and components produced from PET foam cores have proven service life for at least 12 years. At the end of service life, the panels can be delaminated and recycled. Conventional recycling sites would be able to process this material.

Easy installation and usage: PET foam core-based panels and components do not require special installation instructions. Conventional methods and tools can be used to install the panels and components.

Regulatory requirements: Our PET foam core-based panels and components meet federal, state and local regulatory requirements. The panels are IMO-MED certified and meet fire safety standard.

At APM, we are strongly committed to manufacture and supply absolute quality panels and components. Using our products and solutions will guarantee you ultimate performance and service life. At APM, we use premium quality materials and subcomponents to manufacture panels and OEM components. Our production process is completely customized and project specific. All of our panels and components are made to order.

We offer competitive pricing and other benefits, including replacement of products and solutions at no extra cost. We are committed to on-time delivery, and free technical support and consultation whenever necessary. APM offered products and solutions do not contain toxic chemicals or substances. Share your project idea and project specification with us.

Email: contact@advancedmaterialsus.com