Effective insulation of a building greatly helps to save energy bills and improve thermal comfort for the building owner and occupants. Efficient insulation also helps to improve building sustainability and energy rating. Therefore, selecting the right insulation material is crucial. The type of insulation one should choose will depend on a number of factors such as the surface to be insulated, required thermal efficiency and material’s physical and chemical nature. Insulation efficiency of a material is determined by the R-value, higher R-value indicates greater insulation performance. In the simplest terms, R-value is a measure of the insulation's ability to resist heat flow through the material. R-value measured per inch thickness of an insulation material. The R-value depends on the type of insulation, its thickness, and its density. Other factors such as material density, overall weight and thickness. The right insulation material should be resistant to water, solvents and acids. The efficient insulation material also should not lose its insulation efficiency quickly, meaning R-value should be stable over time. The material should be easy to install and provide installation and health safety for the workers. The type of insulation should be chosen based on the climate and the type of building. To ensure you're getting the right insulation for a project, there are four factors to keep in mind: R-value, soundproofing, flammability, and allergens

There is a wide range of insulation materials on the market, but selecting the right insulation material for a project is crucial. Most used insulation materials such as fiberglass, mineral wool and cellulose fibers. These materials resist conductive and convective heat flow in a building cavity. Rigid foam insulation materials such as Polyiso, XPS, EPS trap air or another gas to resist heat flow. Highly reflective foils in radiant barriers and reflective insulation systems reflect radiant heat away, making them particularly useful in cooling climates. Other less common materials such as cementitious and phenolic foams and vermiculite and perlite are also available.

Fiberglass: Fiberglass consists of extremely fine glass fibers and is one of the most ubiquitous insulation materials. Fiberglass insulation is made from molten glass that is spun or blown into fibers. Most manufacturers use up tp 40% to 60% recycled glass content. It's commonly used in many different forms of insulation: blanket (batts and rolls), loose-fill, and is also available as rigid boards and duct insulation. Fiberglass insulation for most projects comes in batts and rolls with R-values ranging from 3 to 49.

Mineral wool: Mineral wool is any fibrous material formed by spinning or drawing molten mineral or rock materials such as slag and ceramics. The term mineral wool is used to describe insulation made from minerals. These minerals include stone, silica and other materials that are extremely resistant to heat. The raw minerals are heated to a high temperature and once molten, spun into fibers. These fibers are then formed into finished insulation products, such as slabs, rolls, etc. Typical R-values for mineral wool ranging from 4 to 60.

XPS and EPS: Extruded Polystyrene insulation (XPS) undergoes a manufacturing process involving extrusion. This method results in a closed-cell structure with dense, smooth skins on both faces, imparting durability and resistance to water penetration. Expanded Polystyrene insulation (EPS), on the other hand, is manufactured using bead foam within a mold. Heat or steam is applied to the beads, causing them to expand and fuse. While EPS also has a closed-cell structure, voids can occur between the beads, potentially compromising its impermeability. Typical R-values for XPS and EPS ranging from 5 to 20

Polyiso: Polyiso rigid insulation boards come in various densities and thickness. It is a closed cell material and produced via chemical reaction of polymer precursor materials in the liquid phase. In the case of polyiso, pentane is used as the blowing agent and during the subsequent development of the matrix, heat is released. The heat causes the dispersed pentane to expand, forming gaseous cells. Typical R-values for Polyiso ranging from 6 to 30.

Rigid PUR and PIR foam materials, EPS and XPS foam materials, Polyiso foam board, Mineral wool blanket and batt, Fiberglass blanket and batt, Cellulose foam board, Laminated PUR and PIR foam board, Laminated EPS and XPS foam board, Laminated Polyiso foam board, Laminated mineral wool board, Laminated fiberglass board, Foil faced PIR, XPS, Mineral wool, Fiberglass glass boards, Melamine insulation foam board, Melamine insulation panel. Thermoplastic laminated PUR and PIR foam panels, Thermoplastic laminated mineral wool panel, Thermoplastic laminated fiberglass panels, Fiberglass laminated PUR and PIR foam panels. Carbon fiber laminated insulation panels and components.

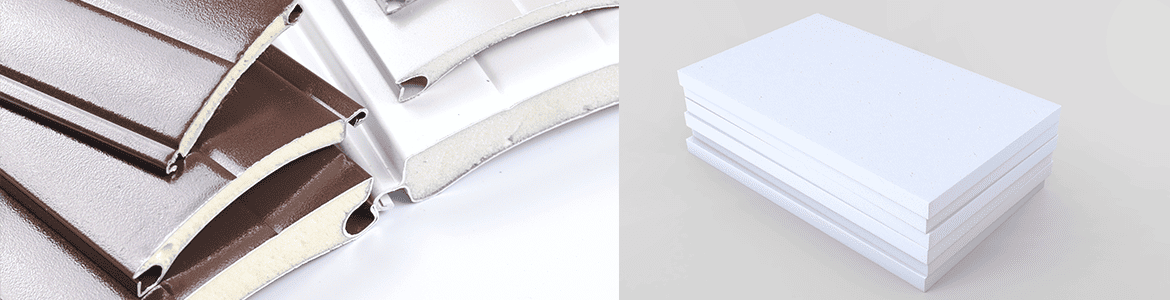

At APM, we laminate Mineral wool board, Fiberglass board, Rigid XPS, EPS, Pur and Polyiso foam boards using a wide range of outer later materials (called skins) to improve insulation performance, appearance, service life and strength. Our lamination process depends on the end project, materials specs and application. Depending on the end project and application we select the outer layer material, adhesive and laminating process. At APM, we have a large selection of outer layer materials and backings such as foil backing laminate, duct laminate, thermoplastic laminate, high pressure laminate, phenolic laminate, fiberglass laminate, carbon fiber laminate and many others. At our production site we have state-of-the-art laminating and composite production equipment. We have the capacity to produce complex shaped and structured panels and components. At APM, we custom produce and fabricate insulation products and solutions depending on the project and application specifications.

Our workshop is well equipped with high-precision CNC and fabrication machines and equipment. We have recently purchased Boeing’s one of two 5-axis CNC machines, and this allow us to fabricate super large insulation panels and composites. At our state-of-the-art production site can be used to fabricate and kerfed complex shaped insulation materials, panels and components. Contact us for your project specification.

This processing is another way to make a structural insulation composite panel to improve the core material’s mechanical and thermal properties. Pre-preg is a common term for composite materials that are “pre-impregnated” with desired resins and then hardened. This pre-impregnation is by various means depending on end-use and application. Contact us for your project specification.

Insulation materials, panels and components are being used in every aspect of a construction project- whether it’s residential, commercial, transportation or marine construction projects. Our produced products and solutions are used in general construction, commercial and residential construction projects, rail interior insulation, trailer manufacturing, cruise and boat interior insulation. A few examples of our materials and solutions- laminated wall insulation panel; non-combustible wall insulation panel; façade insulation panel; non-combustible roof insulation panel; non-combustible insulation panel and components for cruise interior project. Metal composite insulation panels for trailer and transportation container. Fiberglass laminated insulation panel for trucks and trailers, Carbon fiber laminated insulation panel for trucks and trailers, Carbon fiber laminated insulation panel for boat and yacht, Fiberglass laminated insulation panel for boat and yacht. Fabricated insulation OEM parts and components for train, rail, boat and cruise.

At APM, we are strongly committed to manufacture and supply absolute quality panels and components. Using our products and solutions will guarantee you ultimate performance and service life. At APM, we use premium quality materials and subcomponents to manufacture panels and OEM components. Our production process is completely customized and project specific. All of our panels and components are made to order.

We offer competitive pricing and other benefits, including replacement of products and solutions at no extra cost. We are committed to on-time delivery, and free technical support and consultation whenever necessary. APM offered products and solutions do not contain toxic chemicals or substances. Share your project idea and project specification with us.

Email: contact@advancedmaterialsus.com